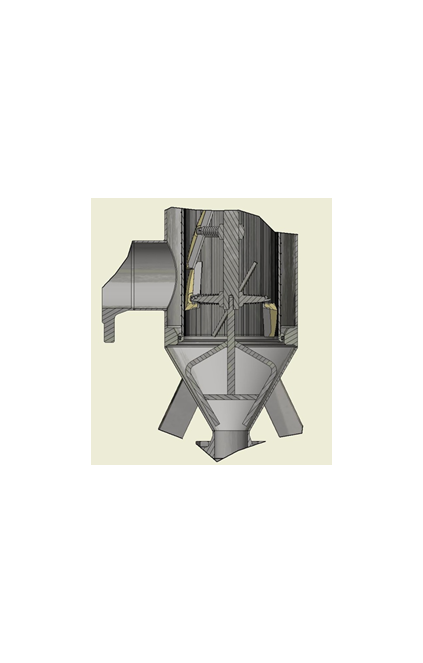

FILTRI IN LINEA AUTOPULENTI

HIFLUX FILTRATION A/S

Esperta in tutte le tipologie di filtri più note (filtri a sacco, a cestello, magnetici, a cartuccia…etc.), ha introdotto sul mercato una novità assoluta nel campo della filtrazione:

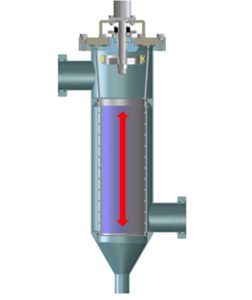

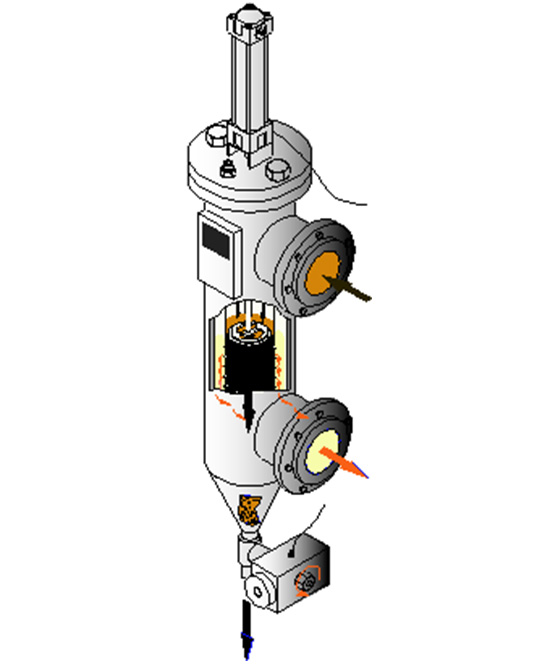

LINEARE

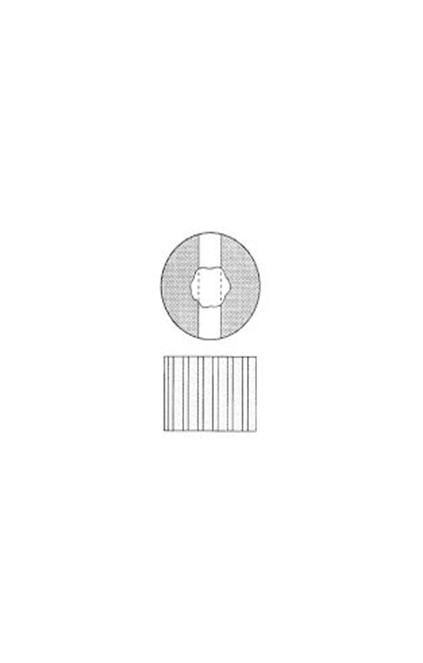

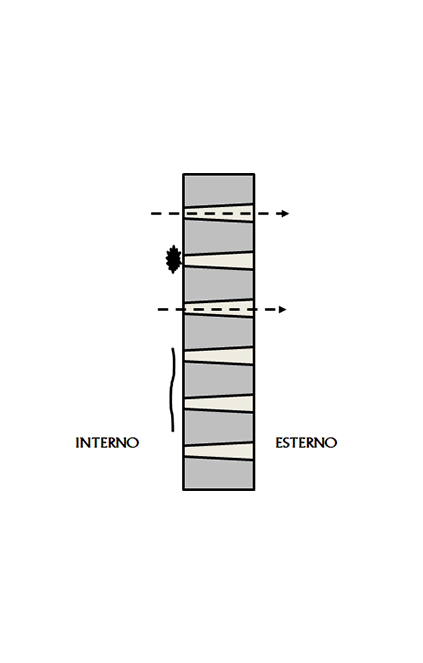

L’unità raschiante (SCRAPER) a forma di disco è aperta nel centro in modo tale che il prodotto possa continuare a fluire senza ostacoli durante la fase di pulizia.

Pulisce la superficie interna del filtro circa 3/4 volte al minuto, spingendo il filtrato verso il cono di scarico.

Lo scraper è a ‘doppia azione’: pulisce in entrambe le fasi di discesa e salita.

Il materiale dello scraper può essere realizzato in:

- PTFE rinforzato al carbonio

- PA (poliammide)

- PEEK (polietere etere chetone)

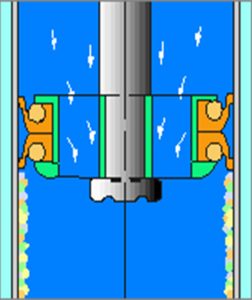

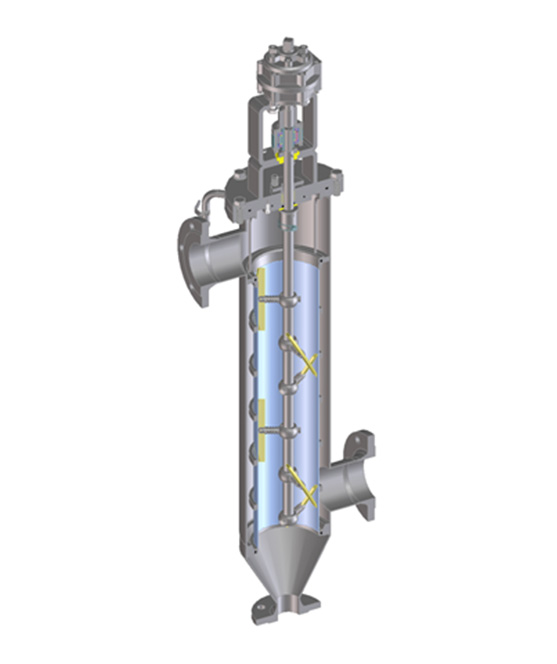

ROTATIVO

Le unità raschianti (SCRAPER) sono angolate e permettono il passaggio del prodotto durante la fase di pulizia.

L’intera superficie interna del filtro viene pulita circa 8 volte al minuto; il prodotto viene spinto verso il cono di scarico

Materiale scraper:

- PEEK (polietere etere chetone)

- POM (poliossimetilene)

CARATTERISTICHE

Filtrazione di particelle dure, soffici e fibrose.

Tre tipologie di elemento filtrante:

- wedge wire

- forato meccanicamente

- forato laser

Range di filtrazione: 30-2000 µm

La selezione viene fatta in base al tipo di prodotto, alla portata, alla viscosità, alla temperatura, alla percentuale di particelle da filtrare, se è un processo a batch o in continuo.

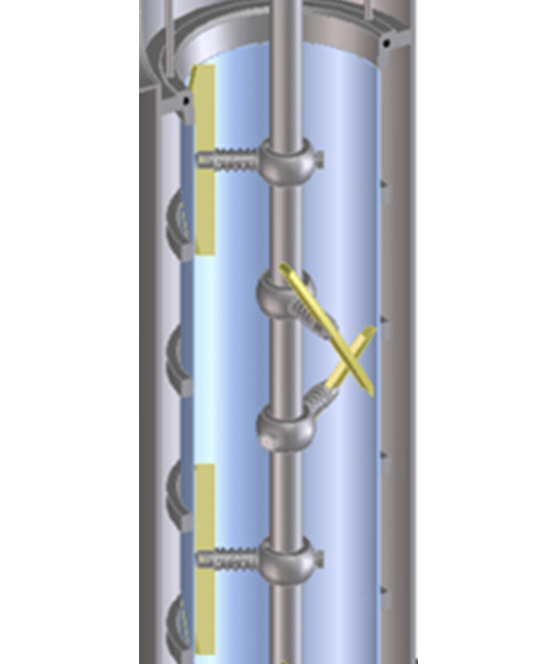

ELEMENTI FILTRANTI

Wedge wire

- Range: 30-2000 µm

- Filtrazione di particelle solide e dure

- Wires: 0.75 o 1.0 mm

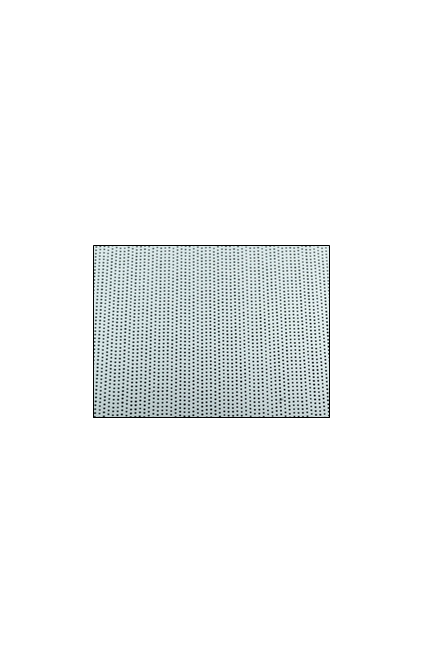

Forati Laser

- Range: 35-400 µm

- Adatto a tutte le particelle (anche fibrose e gel)

Forati meccanicamente

- Range: 500-3000 µm

- Adatto a particelle di taglia superiore

FORATURA LASER

Vantaggi:

- fori conici: per prevenire il blocco di particelle

- filtrazione assoluta (+/- 10 µm)

- filtrazione di particelle dure, soffici/gel e fibre

- superficie interna cromata per aumentare la resistenza al consumo

OPTIONAL

Camicia di riscaldo:

- per mantenere il fluido ad una T fissa in modo da garantire la stabilità/qualità del prodotto

- fino a 270°C

Sistema di sollevamento:

- sistema meccanico per accedere facilmente alla parte interna del filtro in modo da facilitarne le operazioni di manutenzione

Agitatore per cono di dreno:

- per mantenere il filtrato presente nel cono allo stato liquido e per evitare l’accumulo di particelle e il conseguente blocco

Filtro carrellato + pompa a membrana

VANTAGGI

- Il prodotto filtrato ha sempre la stessa qualità

- La filtrazione in continuo permette una portata costante

- Minore perdita di prodotto

- Riduzioni costi smaltimento rifiuti tossici/pericolosi

- Nessun contatto dell’operatore con prodotti ad alta temperatura o pericolosi

Rispetto a soluzioni di filtrazione manuale:

- No fermo impianto dovuto alla rottura/sostituzione del filtro a sacco o cartuccia

- Riduzioni dei costi operativi rispetto a filtri manuali

- No ri-filtrazione dovuta alla presenza di impurità nel prodotto finito

- Nessuno lotto rifiutato a causa della rottura del filtro a sacco

- Minor costi di smaltimento di rifiuti pericolosi

- Minori tempi di filtrazione

COME SCEGLIERE?

DUE TIPOLOGIE PRINCIPALI DI FUNZIONAMENTO: SISTEMA A PISTONE E SISTEMA ROTATIVO…

QUANDO E PERCHÉ UTILIZZARE IL SISTEMA PISTONE

- per produzioni in continuo (frequenza di pulizia controllata mediante ∆P)

- quando la densità delle particelle da filtrare è simile a quella del liquido

- per basse percentuali di sporco: frequenza di pulizia della superficie interna è 2/3 volte al minuto

- per liquidi/particelle ‘shear sensitive’

QUANDO E PERCHÉ UTILIZZARE IL SISTEMA ROTATIVO

- per produzioni a batch

- per alte percentuali di sporco: frequenza di pulizia della superficie interna è di 8 volte al minuto

- se ci sono problemi di ingombro

QUESTE SONO SOLO INDICAZIONI GENERALI…OGNI SPECIFICO PROGETTO VIENE VALUTATO AD HOC!

APPLICAZIONI

SETTORI PRIMARI

- Industria dei coloranti, vernici e coating

- Industria chimica (Inchiostri, resine, adesivi)

- Industria alimentare

- Industria dei polimeri

- Trattamento acqua

- Energia

SETTORI SECONDARI

- Industria farmaceutica

- Acque reflue

- Marino

- Installatori

- Contractor

PROCESSI

PROTEZIONE

Per proteggere le componenti del’impianto contro danni derivanti dalle impurità:

- pompe

- scambiatori di calore

- valvole

- caldaie

- valvole di regolazione

- sfere di lavaggio

RAFFINAZIONE DEL PRODOTTO

Come ultimo passaggio del processo produttivo:

- filtrazione del prodotto finale assicurando sempre la stessa qualità

- rimozione di particelle indesiderate e conglomerati

- ritenzione di particelle desiderate nel fluido

CASE HISTORY

Application:

Automatic filtration of flue gas cooling water in a district heating plant based on biomass.

Case:

The flue gas is sprinkled with water through a series of nozzles (blue arrows), thus cooling the gas. The nozzles are protected against clogging by filtration of the water. Client wants to reuse the sprinkling water after filtration.

- Flow requirement: 43 m3/h

Solution:

HiFlux self-cleaning filter type Auto-line L. Filtration is 2 mm.

Application:

Pre-filtration of geothermal water.

Case:

The client required automatic pre-filtration of the geothermal water in order to extend lifetime on downstream 5-10-micron bag/cartridge filters.

Geothermal water reservoir 2,6 km below terrain.

- Temperature 73 °C

- Pump capacity 230 m3/h

Solution:

HiFlux self-cleaning filter type AKS with 3 nos. wedge wire inserts. Filtration 30 micron. Capacity 230 m³/hour.

Application:

Filtration of animal fats for incineration.

Case:

The client requires automatic filtration of the fat when pumped from the tanker trucks to the storage tanks. The filter is installed in a shed and must be operable by the truck drivers.

- TFiltration: 500 microns

- Flow: Variable

- Pressure: 3-5 bar

Solution:

HiFlux self-cleaning filter type Auto-line XL with ∆P control system type ECII. The filters are traced with heating cables in order to maintain the media in liquid form. Installation in September, 2006.

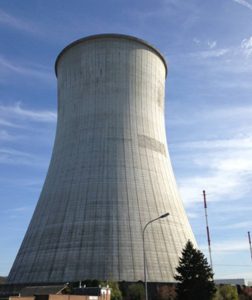

Application:

Filtration of river water for nuclear power plant.

Case:

At 3 positions the client want to take out the river water to use cooling and technical water at the power plant.

- Filtration requirement: 30 or 500 microns

- Flow: 20-25 m3/h per filter

Solution:

3 pcs. HiFlux self-cleaning filters Auto-line M with ∆P control system type ECII and 30 or 500-micron wedge wire elements. Installation in 2011.

Application:

Filtration of cooling water for steel manufacturing.

Case:

In 2012 the open cooling tower was redesigned for capacity of app. 50 MW, and a new self-cleaning filter was required as partial flow filter in the cooling water circuit. An open cooling tower works in a way like a scrubber, i.e. it cleans the air from dust, pollen and other airborne particles. The particles to be filtered out are soft.

- Filtration requirement: 50 µm

- Capacity: 90 m3/h per filter

Solution:

A HiFlux Auto-line XXL filter with electronic differential pressure ECII controller and 50 µm laser bore strainer, operating in a bypass to the main flow.

Application:

Filtration of cleaned sewage water so that it can be used as technical water in the sewage treatment plant. The cleaned water from the filter is used as spraying water on the belt presses and the dewatering units as well as the to flush the centrifuges.

Case:

- Flow: 100 m3/h per filter

Solution:

HiFlux self-cleaning filter type AKS 137 DN100 with electronic differential pressure controller and 100 µm wedge wire strainer. The filter substituted the large 4-unit filter installation seen in the background.

Application:

Filtration of water from sedimentation tanks at waste water treatment plant.

Case:

The water is taken from the sedimentation tanks and used as technical water for cleaning and flushing of process equipment like sand washer, inlet screens and dewatering press (only in closed circuit).

- Flow: 100 m3/h per filter

Solution:

3 nos. HiFlux self-cleaning filters type Auto-line XL with ∆P controller type ECII and 100-micron wedge wire insert.

Application:

Filtration of water from inlet screen at waste water treatment plant.

Case:

The water is taken from the sedimentation tanks and used as technical water for cleaning and flushing of process equipment like sand washer, inlet screens and dewatering press (only in closed circuit).

- Flow: 25 m3/h per filter

Solution:

HiFlux self-cleaning filter type Auto-line M with timer controller for simultaneous filter cleaning and draining based on time interval. Filtration with 100-micron wedge wire insert.

Application:

Filtration of water from clarification tanks at waste water treatment plant.

Case:

The filtered water is used as technical water for cleaning of the filter cloth in the filter press and other equipment. To purpose of the filtration is to protect spray nozzles from blocking with sludge sand and other particles. The client wanted to replace 4 nos. automatic filters type Filtomat, due to time consuming cleaning process and corrosion problems.

- Flow: 0-50 m3/h

- Design pressure: 16 bars

Solution:

HiFlux self-cleaning filter type Auto-line XL with 100-micron wedge wire insert.

Application:

Filtration of waste oil emulsions

Case:

The customer wants to replace bow screen and manual coarse filter with a self-cleaning filter. Very dirty waste oil emulsions with large particles. Product loss during draining must be minimal as drain volume is to be handled as toxic waste.

- Flow: 50-60 m3/h

- Design pressure: 10 bars

Solution:

HiFlux self-cleaning filter type Auto-line XXL with Ø 1,0 mm perforated filter insert. In order to concentrate particles in the drain slurry, the filter is equipped with a sluice vessel with 2 pcs. DN150 knife gate valves. Installation made in April 2015.

Application:

Filtration of wash water from carpet manufacturing process.

Case:

Return water from the carpet manufacturing process is heavily contaminated with fibres, which must be removed before reuse.

- Flow: 20 m3/h at max. 80C°

- Design pressure: 10 bars

Solution:

HiFlux Auto-Line XL self-cleaning filter with linear scraping principle and 200-micron laser bore filter element.

The filter is equipped with electronic differential pressure controller type ECII and DN100 flange drain connection.

Customer supplied Orbinox DN100 knife gate valve with actuator for drain control.

Application:

Filtration of 260 m3/h sweet/brackish water from a canal, used for mixing concrete as building material. Concrete was used for building bridges, track foundation for a high-speed train connection

Case:

Return water from the carpet manufacturing process is heavily contaminated with fibres, which must be removed before reuse.

- Flow: 260 m3/h at max. 80C°

Solution:

HiFlux insulated self-cleaning scraping filter type AKS with 50 µm wedge wire strainer. 3 scraping units was mounted in the same filter housing.

Application:

Filtration of water based exterior paint for houses.

Case:

The client requires automatic filtration and retention of impurities in order to secure the quality of the product before can filling. The filter units must mobile, so they can be moved between the different filling lines and to the cleaning station. Further, the units must be equipped with a membrane pump for pumping the paint into the tank on the filling line.

- Capacity: 25 m3

Solution:

The system consists of 7 pcs. HiFlux Auto-line LR-P self-cleaning filters with oscillating controllers and 800 µm wedge wire strainer, fitted on mobile skid units together with the membrane pumps.

Further 7 pcs. of mobile filter units with manual strainer and pump were supplied for filtration at the tank farm. Installation was made in 2013.

Application:

Filtration of water based paints and wood coating

Case:

The client requires automatic filtration and retention of impurities securing the quality of the product. The product is viscous and with a high content of solid filler material.

Solution:

The system consists of 7 pcs. HiFlux Auto-line LR-E self-cleaning filters with oscillating controllers and 200 µm laser bore filter elements.

Application:

Filtration of water based paint

Case:

Removal of undissolved fillers and gel particles.

- 3 lines: capacity 60-80 m³ per day.

- 3 lines: capacity 10 m³/h, where client wants to avoid manual cleaning of filter housing at colour change. Controls by customer central PLC.

Solution:

The system consists of 6 pcs. HiFlux Auto-line LR-E rotating self-cleaning filters with 200 µm laser bore filter elements.

3 filters are equipped with 3 pcs. flushing ports each for automated cleaning of the filter housing.

Specially designed filter elements for optimal CIP-cleaning.

Application:

Filtration of water based paint.

Case:

The client requires automatic filtration and retention of soft particles when pumping the paint from the mixing tank to the last storage tank (before filling).

- Capacity: 35 m3

Solution:

The client has purchased 2 pcs. HiFlux Auto-line LR-P self-cleaning filters with oscillating controllers and 100 µm laser bore filter element. Installations was made in 2012 and 2013.

Application:

Filtration of water based paint

Case:

The client requires automatic filtration and retention of impurities securing the quality of the product. The product is viscous and with a high content of solid filler material.

Solution:

The system consists of 11 pcs. HiFlux Auto-line XL self-cleaning filters with oscillating controllers and 200 µm wedge wire strainer. Installation was made in 2003.

Application:

Filtration of water and solvent based paint

Case:

Filtration of viscous paint in ATEX area.

- Flow: 22 m³/h

- Filtration: 200 microns

Solution:

HiFlux Auto-Line LR-P rotating self-cleaning filter, fitted on mobile filter unit with Wilden plastic pump and ∆P controller. Pneumatic operation of rotating device and drain valve.

Application:

Filtration of water based paint.

Case:

Replacement of older self-cleaning filter due to high service costs for replacement of filter inserts.

- Flow: 20-25 m³/h

- Retention required: 200 microns

- Particles: undissolved fillers

Solution:

HiFlux Auto-Line XLR-E rotating self-cleaning filter with 200-micron wedge wire filter element. Drain with 2” full bore ball with actuator and timer operation.

Application:

Filtration of roof paint.

Case:

The client had problems with his bag filters for filtration of paint batches of 10-12 m³:

- Filter bags block and interrupts production

- Large waste of finished product when changing bags

- Costly consumption of filter bags & time

Operating temperature: 20°C

Operating pressure: 4 bars

Solution:

The system consists of 2 pcs. HiFlux Auto-line LE self-cleaning filters with oscillating controllers and 200 µm wedge wire strainer. 1” manual ball valves for draining.

Application:

Filtration of wash water

Case:

From the production of steel roof tiles, the client requires cleaning of the wash water containing solvent based paint.

- Flow: 10-20 m³/h.

- Retention required: 100 microns

Solution:

3 pcs. HiFlux Auto-Line M self-cleaning filters with 100-micron wedge wire filter element, ∆P controller type ECII and DN25 full bore ball valve with actuator for purging.

Application:

Isocyanate filtration for a glue manufacturer.

Case:

The filtration is there to remove impurities and crystals formed during transportation and storage in order to secure a homogeneous product.

- Capacity: 15.000 kg/h

- Viscosity: 100 mPas

Solution:

Auto-line XL self-cleaning filter with flushing sealing box is used in connection with unloading of the delivery truck. Further a similar filter is used from storage tank to day production tank. For accurate filtration the filters are equipped with 100 µm perforated laser elements.

Application:

Filtration of distilled tall oil (DTO) resin at 220°C

Case:

Client want to replace manual filters due to:

- heavy work of cleaning and changing

- interruptions in the production line

- risk of accidents with hot fluid

Demands for new filter solution:

- handle flow of 4-8 m3/h at viscosity 16 cSt at 180 °C

- 300-micron filtration

- design temperature 350°C

- design pressure 16 bar / work pressure 4 bar

- no pressure drops when draining dirt particles

- easy to serve and reliable functions

Solution:

Auto-Line XL self-cleaning filter with:

- filter housing with heating jacket manufactured acc. to PED 97/23/EU Category III, Module G.

- double pneumatic side mounted cylinders

- 10 l drain chamber (with heating jacket) to prevent pressure drop when draining

- Filter element 300-micron laser bored, 1.4404

- O-rings: Isolast

- Cylinder packing and scrapers: PEEK FC30

Application:

Filtration of melamine glue for chipboard production.

Case:

The client wants to place a filter at the filling station for the tanker trucks, in order to:

- Replace a bag filter and eliminate large consumption of filter bag

- Retain gel and skin particles

- Reduce product loss

- Reduce time consumption for truck filling

Flow: 40 m3/h

Viscosity: 3.500 cSt at 40°C

Filtration requirement: 400 microns.

ATEX area.

Solution:

HiFlux self-cleaning filter type Auto-Line XLR-E with 400-micron laser bore filter element and ATEX-approval.

Application:

Filtration of hot melt glue at a manufacturer in Italy.

Case:

Filtration of hot melt glue before filling into drums or plastic “pillows”.

- Flow: 1,0 – 1,5 ton/hour

- Particles: mixture of hard and soft

- Retention required: 100 microns

- Design temperature: 200°C

Solution:

The customer has 3 pcs. HiFlux Auto-Line XLR-E self-cleaning filters with heating jackets and 100-micron laser bore filter elements.

The filters are equipped with electronic differential pressure controller type S11 and 1½” full bore drain ball valve with actuator.

Application:

Filtration of solvent-based adhesive as part of a commercial printing project.

Case:

The client wants to replace disposable filters which clog up during the discharge procedure and needs replacing regularly.

- Flow: 1,2 m3/h (batch)

- Viscosity: 55 cSt.

- Filtration of soft particles at 50 microns.

- ATEX area.

Solution:

A HiFlux self-cleaning filter type Auto-Line M with 50-micron laser bore filter element was positioned before the disposable filter, to remove the majority of the particles.

In addition to reducing the number of disposable filters needed, the HiFlux unit resulted in a more sustainable operation, as the life span of the throwaway filters was extended up to five times longer than before.

As a result, the customer has sent fewer filters to landfill and cut its weekly operational costs by £1,725. Controller is continuous oscillating, draining is manual.

Application:

Filtration of resin dispersions

Case:

Client wants to replace manual filters and vibrating sieves for:

- Better quality by removing particles/impurities

- Closed system in order to avoid foam

Demands for new filter solution:

- Handle flow of 20 m³/h

- Viscosity 300-500 cP at 20°C

- Filter retention: 150-250 micron

Solution:

HiFlux Auto-Line XXLR-E rotating self-cleaning filter with 150-micron laser bored filter element, scraper axle with double scrapers and agitator for drain cone. Timer operated 2” full bore drain ball valve with actuator, and push-button.

Application:

Filtration of wood glue based on polyvinyl acetate (PVA).

Case:

The client wants to place a filter at the filling station, guarding that no gel or skin particles pas into the packaging, thus securing quality and continuous smooth running of the filling station.

- Flow: 6 m3/h

- Viscosity: 10.000 mPas

- Design pressure: 10 bars

- Design temperature: 80°C

- Filtration of soft particles at 200 microns.

Solution:

HiFlux self-cleaning filter type Auto-Line XL with double cylinder and 200-micron laser bore filter element. Controller is continuous oscillating during filling, drain is manually operated.

Application:

Filtration of ink base before filling.

Case:

Client wants to automate his filtration process before filling of IBC-containers, but is very concerned about “pushing” soft/fragile particles through the filter element.

Demands for new filter solution = Filter retention: 150 microns

Solution:

HiFlux Auto-Line XL self-cleaning filter linear scraping principle and 150-micron laser bore filter element. The filter is equipped with electronic differential pressure controller type ECII and 2” full bore drain ball valve with actuator.

Application:

To filter an organo-metallic soap, comprising 22.5% metallic Cobalt, in a resin base. Product employed as a bonding agent in tire manufacture, to glue rubber to metal.

- Through-flow: 6.3 tons batch

- Density: 1100 kg/m3

- Viscosity: 20,000 Pa

- Temperature: 150oC

- Filtration: 50 microns

- EX-area

Case:

The application was to replace a DN450 Spirax Basket Filter, which lost the customer product valued at £6000/tons.

Solution:

Auto-line LE self-cleaning filter with ATEX approved pneumatic controller and 50-micron laser-bore element. Filter equipped with heating jacket, as the product solidifies at 60°C.

Application:

Filtration of ink base before filling.

Case:

In order to secure product quality, the client wants to place a filter at the filling station for tanker trucks. Many tanker trucks are not 100% clean, and the client wants to ensure that the bio diesel doesn’t contain particles larger than 75 microns.

Solution:

HiFlux self-cleaning filter type KS-137 with and 75-micron wedge wire filter element. The filter is equipped with on/off, so that it starts when the feed pump to the tanker trucks starts.

Application:

Filtration of fat fraction from a process plant for animal by-products.

Case:

The client wants to secure the quality of the product by removing plastic tags and bone fractions from the fat. The product is hot and viscous and with a moderate content of solid material.

Solution:

A self-cleaning Auto-line XL filter with Ø 500 µm perforated strainer was installed. A sluice system is mounted in the drain to concentrate dry matter in the sludge as much as possible. Installation was made in 2003.

Application:

Filtration of cooling water at the largest manufacturer of plastic parts.

Case:

Client is looking for an automatic and cost-effective solution for filtration of cooling water from 12 factory modules with 50 machines each. Currently each machine has one 10” cartridge filter, and the cartridge is exchanged once every week.

Solution:

12 nos. HiFlux Auto-line XL self-cleaning filters. 1 no. per factory module for filtration of 50 m³/h from 50 machines, at 3-4 bar pressure, temperature 17°C and 100-micron filtration.

HiFlux ECII Dp controller with transmission of pressure and alarm signals to the clients own control system.

Application:

Filtration of paper filling media for manufacturing of quality paper.

Case:

Flow rate = variable from 3 to 15 m3/h.

Solution:

The system consists of 1 pcs. HiFlux self-cleaning filter type KS 137, mounted with a sludge chamber at the drain to prevent pressure drop when the drain opens. The filtration rate is 130µm wedge wire. Installation was made in 2006 and the customer made the control system for the filter.

CERTIFICAZIONI

- Realizzato in accordo alle direttive EC per sistemi sotto pressione PED 2014/68/EC e può essere fornito in accordo alle categorie I, II, III o IV

- Disponibile la versione ATEX, zone 1/21 e 2/22, in accordo alla direttiva 94/9/EC

- In accordo alla direttiva EC1935/2004 e FDA standard per polimeri ed elastomeri. Tracciabilità totale dal produttore fino al cliente finale, certificato dalla Danish Food Authorities

- Progettato secondo le linee guida dell’EHEDG